- 您现在的位置:买卖IC网 > Sheet目录501 > PTGL18AR120M9C01B0 (Murata Electronics North America)THERMISTOR

�� �

�

�

�!� Note� ?� Please� read� rating� and� !� CAUTION� (for� storage,� operating,� rating,� soldering,� mounting� and� handling)� in� this� catalog� to� prevent� smoking� and/or� burning,� etc.�

�?� This� catalog� has� only� typical� speci?cations.� Therefore,� please� approve� our� product� speci?cations� or� transact� the� approval� sheet� for� product� speci?cations� before� ordering.�

�!� Caution/Notice�

�c� Notice� (Soldering� and� Mounting)� PRF18/21� Series�

�1.� Solder� and� Flux�

�R90E.pdf�

�Mar.4,2014�

�(1)� Solder� Paste�

�(a)� Flow� Soldering:� Use� Sn:Pb=60:40wt%,�

�Sn:Pb=63:37wt%,� Sn:Ag:Cu=96.5:3.0:0.5wt%� or�

�equivalent� type� of� solder.�

�(b)� Reflow� Soldering:� Use� Sn:Pb=60:40wt%,�

�Sn:Pb=63:37wt%,� Sn:Ag:Cu=96.5:3.0:0.5wt%� or�

�equivalent� type� of� solder� paste.�

�For� your� reference,� we� are� using� "63Sn/37Pb�

�RMA9086� 90-3-M18,"� manufactured� by� Alpha� Metals�

�Japan� Ltd.,� "96.5Sn/3.0Ag/0.5Cu�

�M705-GRN360-K2-V,"� manufactured� by� Senju� Metal�

�Industry� Co.,� Ltd.� for� any� internal� tests� of� this� product.�

�2.� Cleaning� Conditions� and� Drying�

�To� remove� the� flux� after� soldering,� observe� the� following�

�points� in� order� to� avoid� deterioration� of� the� characteristics�

�or� any� change� to� the� external� electrodes'� quality.�

�(1)� Cleaning� Conditions�

�(2)� Flux�

�Use� rosin� type� flux� in� the� soldering� process.�

�If� the� flux� below� is� used,� some� problems� might� be�

�caused� in� the� product� characteristics� and� reliability.�

�Please� do� not� use� these� types� of� flux.�

�0.2wt%).�

�(*Water-soluble� flux� can� be� defined� as� non-rosin� type�

�flux� including� wash-type� flux� and� non-wash-type� flux.)�

�Solvent�

�2-propanol�

�Dipping� Cleaning�

�Less� than� 5� minutes�

�at� room� temp.�

�or�

�Less� than� 2� minutes�

�at� 40?C� max.�

�Ultrasonic� Cleaning�

�Less� than� 1� minute�

�20W/L� Frequency�

�of� several� 10kHz�

�to� 100kHz.�

�A� sufficient� cleaning� should� be� applied� to� remove� flux� completely.�

�(2)� Drying�

�After� cleaning,� promptly� dry� this� product.�

�3.� Soldering� Conditions�

�In� your� mounting� process,� observe� the� following� points� in�

�order� to� avoid� deterioration� of� the� characteristics� or�

�destruction� of� this� product.� The� mounting� quality� of� this�

�product� may� also� be� affected� by� the� mounting� conditions,�

�shown� in� the� points� below.�

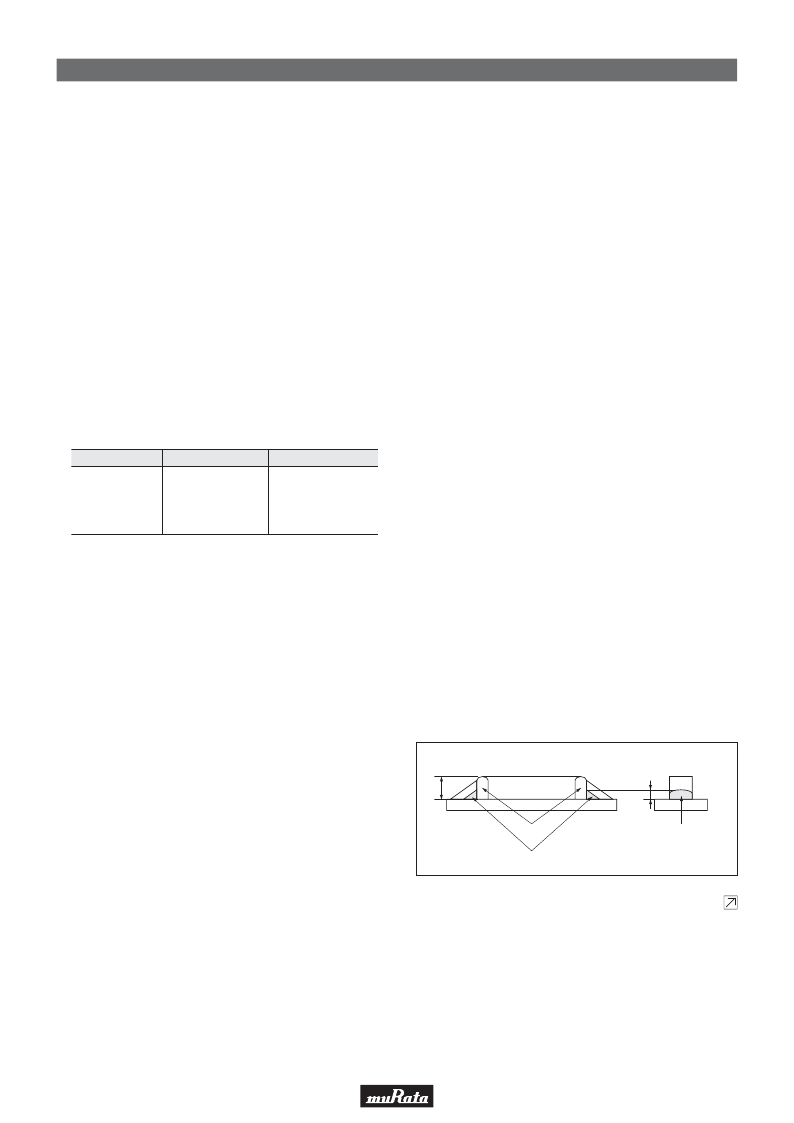

�(1)� Printing� Conditions� of� Solder� Paste�

�(a)� Recommended� thickness� of� solder� paste� printing�

�should� be� from� 0.15� to� 0.20mm.�

�(b)� After� soldering,� the� solder� fillet� should� be� a� height�

�from� 0.2� mm� to� the� thickness� of� this� product� (see� the�

�figure� at� right).�

�(c)� Too� much� solder� result� in� excessive� mechanical�

�stress� on� this� product.� Such� stress� may� cause�

�cracking� or� other� mechanical� damage.� Also,� it� can�

�E�

�Electrode�

�Solder�

�T�

�Solder�

�0.2mm� V� T� V� E�

�destroy� the� electrical� performance� of� this� product.�

�Continued� on� the� following� page.�

�96�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

PTRF1221IRGZR

PTRF1221IRGZR

PTWSB2AG201T260A00

THERMISTOR PTC CER HEATER 200C

PWA-RD1C-1W-WSP

PWAR WARM WHITE SPOT W DRIVE

PWM-RD1C-1W-WSP

PWMR WARM WHT SPOT W DRIVE

Q12P1CXXY110E

INDICATOR 110V 12MM PROM YELLOW

Q14P1CKKR24E

INDICATOR 24V 14MM PROMINENT RED

Q16F1BXXW110E

INDICATOR 110V 16MM FLUSH WHITE

Q19P1BXXW110E

INDICATOR 110V 19MM PROM WHITE

相关代理商/技术参数

PTGL18AR2R3H4B71B0

功能描述:热敏电阻 - PTC 2.3ohm +/-25% PTC Thermistor

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18AR3R3M6B72B0

功能描述:热敏电阻 - PTC 3.3ohm +/-20% PTC Thermistor

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18AR4R7M6B72B0

功能描述:热敏电阻 - PTC 4.7 OHM 20%

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18AR4R7M6C01B0

功能描述:热敏电阻 - PTC 4.7ohm +/-20% PTC Thermistor

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18AR6R0H8B72B0

功能描述:热敏电阻 - PTC 6 OHM 25%

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18AR6R8M6B72B0

功能描述:热敏电阻 - PTC 6.8ohms

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL18ARR45H2B71B0

功能描述:热敏电阻 - PTC 0.45ohm +/-25% PTC Thermistor

RoHS:否 制造商:Vishay 电阻:1.5 kOhms 容差:1 % 端接类型:Radial 系列:TFPTL 工作温度范围:- 55 C to + 70 C

PTGL20AS330H0D02BZ

制造商:MURATA 制造商全称:Murata Manufacturing Co., Ltd. 功能描述:POSISTOR for Circuit Protection